-

-

Composite Salt Spray Test Machine

Model: YWX/Q-010X

YWX/Q-150X series Composite Salt Spray Test Machine fullly compliance with GB/T 2423. 18, GB/T-10125, IEC 60068-2-11, GMW 14872, TCSAE 71, VCS 1027_1449, PV 1210,etc standards requirements. It do measurement through simulating conditions that are more commonly encountered in the natural environment such as salt spray, hot air drying, humidity, low temperature combined and loop in any order. It is widely used to test items used in drastically changing environments, such as automobile parts, aviation equipment, building materials, coating, electric and electrical machinery so on.

Product models:

| Model | Work Room Size (mm) | Voltage | Power (KW) |

| YWX/Q-250X | 900×600×500 | AC380 | 10 |

| YWX/Q-010X | 1200×800×500 | AC380 | 12 |

| YWX/Q-016X | 1600×900×600 | AC380 | 16 |

| YWX/Q-020X | 2000×1000×600 | AC380 | 20 |

Specifications:

• Test temperature range: +20℃~+80℃

• Relative humidity: 30%~98%RH (±3%)

• Saturated barrel temperature: 47℃~70℃

• Temperature uniformity: ≤±2℃

• Temperature fluctuation: ≤±1℃

• Test time:0-999H, M (Adjustable)

• Settlement: 1-2ml/80cm²/h

• Spray method: Programmable spray, dry, wet

• Demisting way: Exhaust fog by extrusion the air

• Sample holder: Meet the standard requirements

Test Principle:

Composite Salt Spray Test Machine is composed of the cyclic corrosion test of the spray process, the damp and heat process, and the standing and drying process. The following are the schematic diagrams of these three processes:

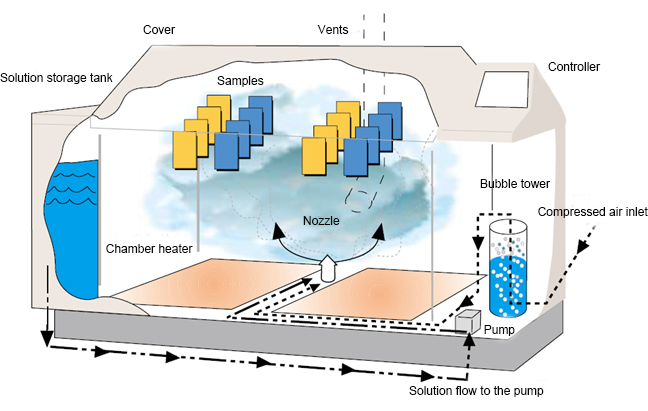

1. Spray process

The system consists of salt water tank, pneumatic system, salt water storage tank, spray tower, nozzle, etc. The salt solution flows from the outside to the test chamber by using the natural drop, and the salt solution is atomized by compressed air through the spray nozzle.

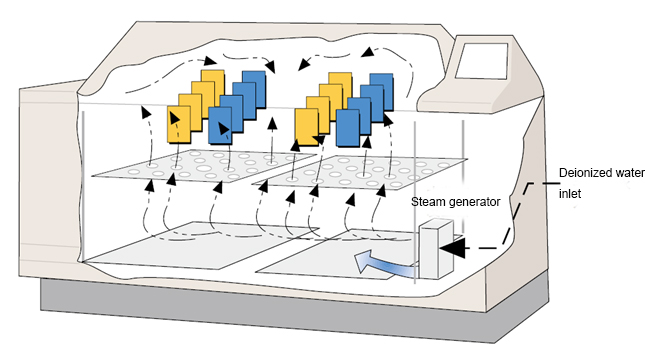

2. Damp heat test

The damp heat test system is composed of steam generator, blast, water circuit, condensation device, etc. After the salt spray test, the machine will set up a defogging program to discharge the salt spray out of the test room as soon as possible; Then the water evaporator will output the appropriate temperature and humidity according to the temperature and humidity set by the controller. Generally speaking, the humidity will be more accurately calibrated and constant after the temperature is stable. The temperature and humidity parameters of the damp heat test are as follows: Temperature: 30℃—60℃; humidity: 80%RH—98%RH.

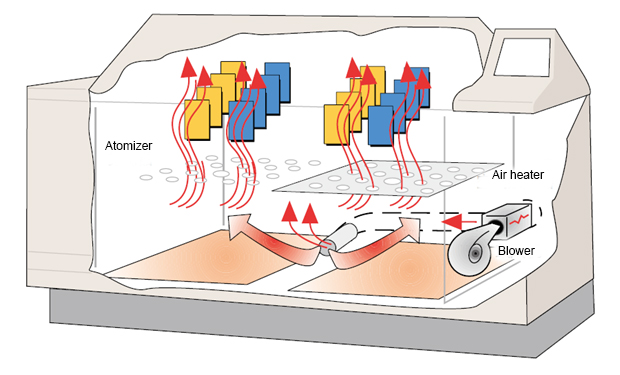

3. Drying process

Standing and drying system adds drying blower, heating wire, air filter and other devices on the basis of damp heat system, if need to simulate standard atmospheric pressure environment test (temperature 23℃±2℃, humidity 45%~55% RH). Firstly, quickly remove the damp and heat test environment in the previous section by setting a defogging program to create a relatively clean test environment, and then the humidifier or dehumidification system works in coordination under the controller to produce an environment that meets the test requirements. The temperature and humidity parameters of the drying test are as follows: temperature: 20℃-60℃; humidity: 30%~60%RH (corresponding to the appropriate temperature point).